Rapid Prototyping Made in China: A Comprehensive Guide

Rapid prototyping made in China has emerged as a game-changer in global manufacturing, particularly for businesses seeking to innovate in product development. This technology allows companies to swiftly create prototypes, test concepts, and refine designs, streamlining the overall manufacturing process. In this article, we will explore the fundamentals of rapid prototyping, the unique advantages of outsourcing this function to China, and how it can profoundly impact your business strategy.

Understanding Rapid Prototyping

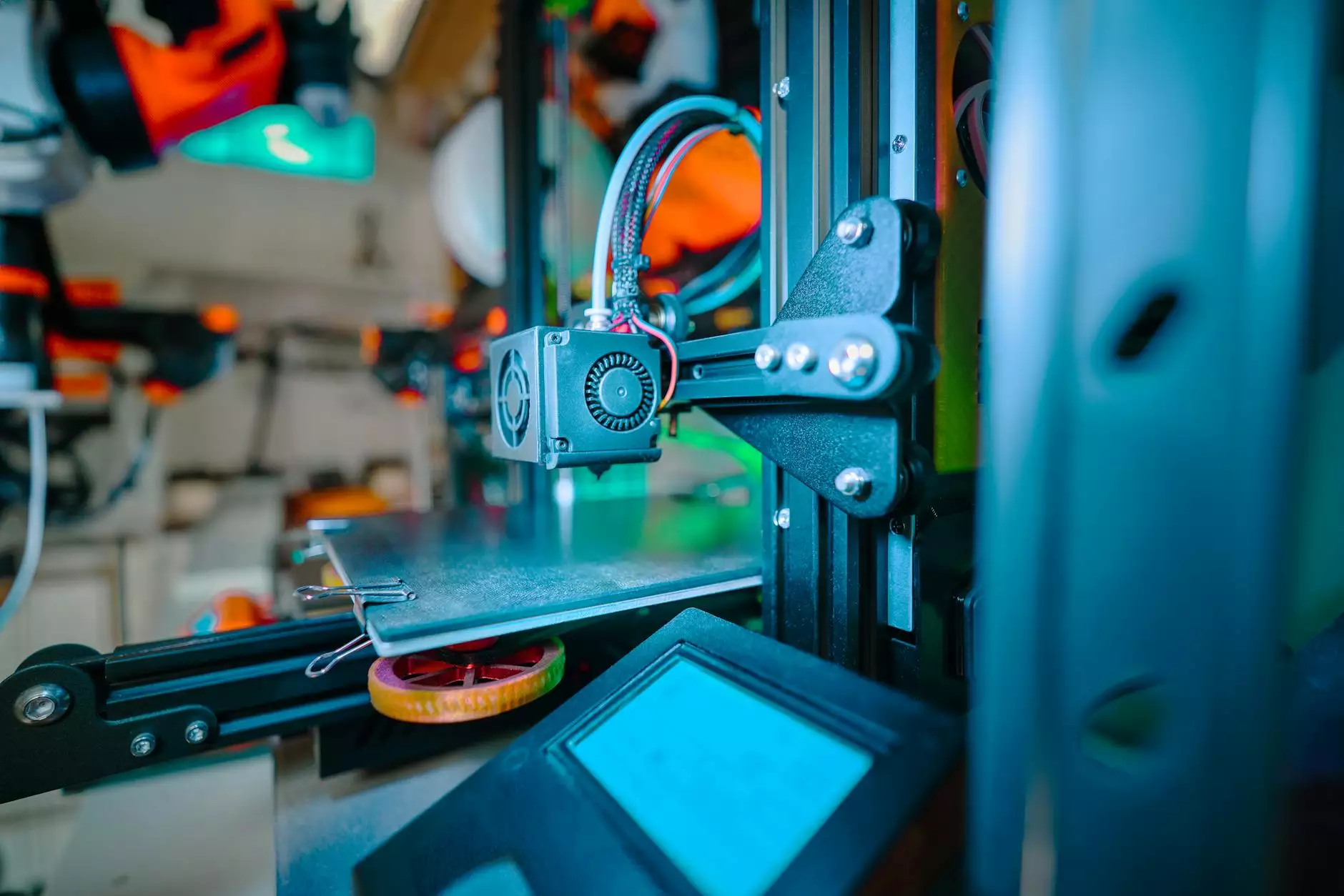

Rapid prototyping is a set of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. The main goal of rapid prototyping is to enable a faster and more efficient design process, reducing the time and costs associated with traditional manufacturing methods.

There are several technologies utilized in rapid prototyping, including:

- Stereolithography (SLA): An early and popular 3D printing technology that uses a laser to cure liquid resin into solid forms.

- Fused Deposition Modeling (FDM): A method that uses a continuous filament of thermoplastic to build parts layer by layer.

- Selective Laser Sintering (SLS): A technology that uses a high-powered laser to fuse small particles of polymer powder into solid structures.

- CNC Machining: A subtractive method that uses computer-controlled cutting tools to create parts from solid blocks of material.

The Advantages of Rapid Prototyping Made in China

The advantages of rapid prototyping made in China are numerous and impactful for businesses around the world. Here are some key benefits:

1. Cost Efficiency

One of the most compelling reasons to choose rapid prototyping providers in China is the significant cost savings. Labor costs in China are typically much lower than in Western countries, allowing manufacturers to offer competitive pricing without sacrificing quality. This reduction in costs translates to lower expenses for your project, enabling you to allocate resources to other critical areas of your business.

2. Advanced Technology and Expertise

China has invested heavily in advanced manufacturing technologies, resulting in highly capable facilities capable of executing rapid prototyping with precision and speed. Many companies in China specialize solely in rapid prototyping, bringing years of expertise and a strong understanding of global markets. This specialization ensures that your prototypes are manufactured to the highest standards.

3. Speed and Efficiency

Rapid prototyping is designed to be quick, and when processed in China, it can be faster than in many other regions. With a vast network of suppliers and manufacturers working collaboratively, the cycle time from design to prototyping can be dramatically shortened. This rapid cycle allows businesses to test and iterate designs efficiently, reducing the time to market for new products.

4. Scalability

When your prototype is ready for full-scale production, transitioning from small-batch prototyping to mass production is seamless. Many rapid prototyping companies in China are equipped to scale up production quickly while maintaining quality standards. This adaptability is crucial for businesses that anticipate fast growth or fluctuations in demand.

5. Customization and Adaptability

China's manufacturing flexibility allows for high levels of customization in prototyping. Whether you need specific materials, sizes, or design modifications, Chinese manufacturers can often accommodate these requests more easily than those in more rigid production environments.

How to Choose a Rapid Prototyping Partner in China

Finding the right rapid prototyping partner in China is essential to the success of your project. Here are key factors to consider:

1. Experience and Reputation

Research potential partners thoroughly. Look for companies with a solid track record in rapid prototyping and positive reviews from previous clients. Websites like deepmould.net can provide insights into the capabilities and reviews of various manufacturers.

2. Technology and Capabilities

Ensure that the company you choose utilizes the latest technologies relevant to your project. Not all prototyping companies have the same capabilities; therefore, it’s crucial to understand what manufacturing processes they offer and whether they match your specific needs.

3. Communication and Support

Good communication is vital when working with overseas manufacturers. Partner with a company that offers clear communication channels and has a responsive support team. Language barriers should not prevent effective collaboration.

4. Quality Assurance

Make sure your chosen manufacturer has quality assurance protocols in place. This will ensure that your prototypes meet your standards and function as intended. Request samples or case studies to review their quality metrics.

Case Studies: Success Stories of Rapid Prototyping Made in China

Case Study 1: Consumer Electronics

A leading consumer electronics brand required rapid prototyping for a new line of smart home devices. By collaborating with a Chinese prototyping firm, they reduced their prototyping time by 60%. The cost savings allowed them to reinvest in marketing and expand their product line more aggressively.

Case Study 2: Automotive Industry

An automotive manufacturer needed to develop a new car component. Utilizing rapid prototyping in China allowed them to create and iterate designs quickly. This accelerated development process led to a successful launch of the component several months ahead of competitors.

The Future of Rapid Prototyping Made in China

The future of rapid prototyping made in China holds immense potential. As technologies evolve, including advancements in artificial intelligence and automation, we can expect rapid prototyping processes to become even more efficient. Additionally, the rise of sustainable manufacturing practices will influence prototyping methods, driving innovations that reduce waste and improve environmental impact.

Conclusion

Investing in rapid prototyping made in China can significantly enhance your business's ability to innovate and respond to market demands. With benefits such as cost efficiency, speed, scalability, and access to advanced technologies, it’s no surprise that more businesses are turning to Chinese manufacturers for their prototyping needs. By carefully choosing the right partner and leveraging the advantages of rapid prototyping, your business can stay ahead of the competition and foster a culture of continuous improvement and innovation.

For more information on rapid prototyping solutions, visit deepmould.net and discover how we can help streamline your product development process.